Over a century ago, Leon Brillouin described the inelastic scattering of light by acoustic phonons but only now, over a 100 years later, is its potential application in Brillouin Microscopy for practical exploration of the mechanical properties of biological tissues beginning to be realised. Central to this advance is the development of virtually imaged phased arrays (VIPAs).

This article discusses how Brillouin microscopy is used for life science applications, why VIPAs are an essential component in the spectrometers used and the critical role of exacting surface flatness and coating specifications needed for an effective VIPA. We start then with a summary explanation of Brillouin scattering before providing an overview of the microscopy applications such as cancer diagnostics, corneal biomechanics, and tissue engineering that it is used for.

What is Brillouin scattering and how is it the basis for Brillouin microscopy?

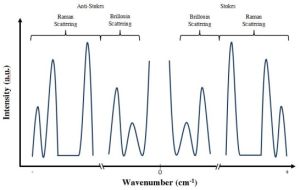

When light waves composed of photons collide with solid materials which have been excited by a sound wave composed of phonons (ascribing a particle nature to the wave inside the material), the law of physics prescribes that overall momentum and energy are conserved. During this inelastic scattering process, a phonon can be created or destroyed and it can therefore gain or lose energy.

When looking at the spectrum of the scattered light, this process causes two additional peaks, namely the Stokes (in case of phonon emission) and the anti-Stokes peak (in case of phonon absorption. Analysing the resulting spectrum and the spectral position of the peaks can be utilised to gather information about the mechanical properties of the relevant material

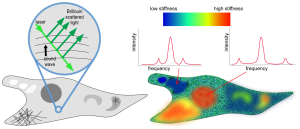

Brillouin microscopy is an optical imaging technique that allows researchers to explore the mechanical properties of biological tissues at a microscopic level using Brillouin scattering. By analysing the interaction of light with acoustic waves in a sample, this non-invasive method provides valuable insights into molecular properties such as tissue stiffness, elasticity, and viscosity. For applications such as disease diagnostics and cellular mechanics, Brillouin microscopy offers a unique lens into the biomechanical world.

Brillouin Microscopy in Biomedical Applications

Brillouin microscopy offers both researchers and clinicians an understanding of the mechanical properties of cells and tissues, revealing crucial information about their structure and function. The technique is uniquely positioned to contribute to this understanding, offering high-resolution, label-free and dye-free imaging of elasticity and viscoelastic properties. For example, in cancer research, Brillouin microscopy can help differentiate between healthy and malignant tissues based on their biomechanical characteristics. Similarly, it is employed in corneal biomechanics to assess conditions such as keratoconus or evaluate the efficacy of corrective treatments. Tissue engineering and regenerative medicine are other areas where this technology is starting to prove indispensable, enabling researchers to monitor the biomechanical properties of engineered tissues in real-time.

At the core of these applications lies the need for highly precise and efficient optical systems. The ability of Brillouin microscopy to deliver accurate data relies not only on its underlying principles but also on the quality of the components that drive it – particularly the spectrometry systems responsible for resolving minute frequency shifts.

What Makes VIPAs Critical for Brillouin Microscopy?

Resolving the minute frequency shifts and peaks and analysing the peaks in them requires technically very advanced spectrometers. Traditional spectrometers using a grating or a prism are just not sensitive enough and so it is necessary to use Fabry-Perot spectrometers.

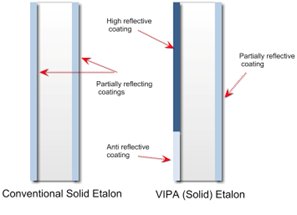

Traditional Fabry-Perot spectrometers are relatively slow however and so this is where a virtually imaged phased array (VIPA) etalon becomes necessary. Fundamentally a VIPA is very similar to a standard solid etalon with the main difference being in the coating of the two opposing surfaces.

VIPAs are key components in the spectrometers used for Brillouin microscopy. These devices enable the separation and measurement of the tiny frequency shifts caused by Brillouin scattering, which typically occur in the gigahertz range. Compared to traditional diffraction gratings, VIPAs offer a much higher spectral resolution and throughput, making them ideal for resolving the fine details required in biomedical applications.

In a Brillouin microscopy setup, the light scattered by the sample contains critical information about its mechanical properties. The VIPA etalon acts as the heart of the spectrometer, directing and dispersing the scattered light to allow precise measurement of its frequency components. This capability is essential for distinguishing subtle variations in tissue mechanics, which can be the difference between accurate diagnostics and inconclusive results.

Surface Flatness and Coating Quality: Why They Matter

Surface Flatness

Surface flatness is critical for ensuring the integrity of the wavefront passing through the VIPA etalon. Any irregularities on the surface can introduce optical aberrations, distorting the light path and reducing the overall resolution of the spectrometer. For Brillouin microscopy, where even minute errors can compromise the accuracy of biomechanical measurements, maintaining wavefront fidelity is essential. A high degree of surface flatness ensures that the light is directed precisely, preserving the clarity and detail needed to analyse delicate biological samples.

Coating Quality

Equally important is the quality of the coatings applied to the VIPA etalon. These coatings are responsible for controlling the reflectivity and transmission of light, which directly affects the device’s efficiency. Anti-reflective coatings minimise energy loss and maximise throughput, while reflective coatings ensure proper beam manipulation within the device. For biomedical applications, where high optical intensities may be used, the durability and uniformity of these coatings are vital. Poor-quality coatings can degrade under high-intensity light, leading to inconsistent performance or even component failure.

Together, surface flatness and coating quality determine the ability of VIPA etalons to provide the high spectral resolution and reliability demanded by users of Brillouin microscopy systems. In applications such as tissue diagnostics or cellular mechanics, there is no room for compromise.

WRAP UP

As Brillouin microscopy unlocks new possibilities in biomedical research and diagnostics, the importance of the spectrometry systems responsible for resolving minute frequency shifts and their high-quality optical components cannot be overstated.

VIPA etalons, with their unparalleled ability to resolve minute frequency shifts, are at the forefront of this advance in technology. Ensuring superior surface flatness and coating quality is essential to maximising the performance of these critical components, enabling researchers and clinicians to extract accurate, meaningful data from their investigations.

With the right components in place, Brillouin microscopy systems are poised to push the boundaries of discovery and deliver transformative insights into the biomechanical properties of life itself, particularly through the rapid analysis capabilities of VIPAs, which enable real-time applications in life sciences.

Contact us to find out more about VIPA etalons.

Further Reading

Insight Articles

- 125 Years of Etalons: Celebrating the enduring legacy of Charles Fabry and Alfred Perot

- Technical note: Etalons Explained