ULTRAFAST POLARISERS

MPO’s high energy ultrafast cube and plate polarisers offer broadband spectral and optimised group dispersion delay (GDD) performance.

Our cube polarisers offer exceptional resistance to laser damage through the use of optical contacting process, rather than the use of epoxies or optical cements that lower the laser-induced damage threshold (LIDT).

Polarisation optics for ultrafast lasers have to work over a relatively broad spectral range, generally from 700-900nm or 750-850nm. There are two options, cube or plate polarisers. Both offer the highest LIDTs, optimum GDD and spectral performance.

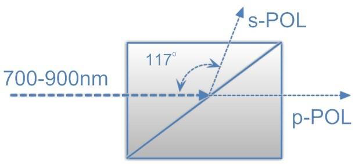

CUBE POLARISERS

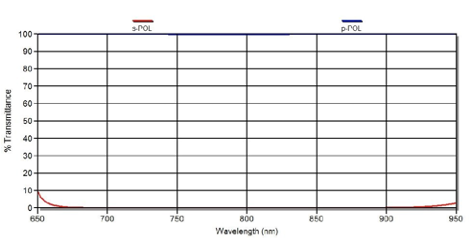

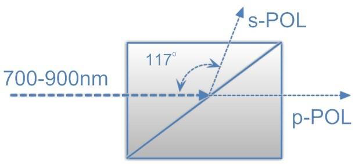

The operational bandwidth of a cube polariser is to a large extent determined by the refractive index of the prisms forming the cube. To maintain a high LIDT, it is necessary to use fused silica as the substrate material for the prisms. As with plate polarisers, standard polarisation cubes have a narrow operational bandwidth of only 5-10nm. However, it is possible to increase this operational bandwidth to cover the 700-900nm range by increasing the angle of incidence on the immersed polarisation coating. As a result, the cube polarisers for ultrafast applications are often called “stretched” or “extended” cubes – being longer in one axis in comparison to single wavelength cubes. These “extended” optically contacted cubes offer a very good extinction ratio in excess of 200:1 while being able to withstand the high laser power levels they are generally exposed to.

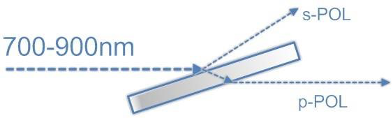

PLATE POLARISERS

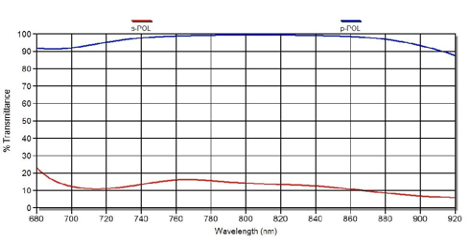

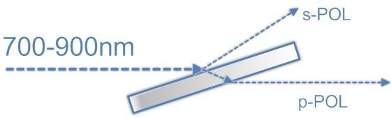

A plate polariser working at Brewster’s angle (57°) only covers a very narrow bandwidth of typically 5-10nm. To increase the working bandwidth, the angle of incidence needs to be increased to typically 72°. At this angle of incidence it is possible to achieve polarisation over the required 700-900nm bandwidth but this increase in operational bandwidth also brings with it a significant reduction of the extinction ratio. While Brewster polarisers typically have an extinction ratio in excess of 200:1, plate polarisers at 72° for ultrafast lasers only offer an extinction ratio of approx. 5:1. They can, however, be optimised to maximise the reflectivity of s-POL or the transmission of p-POL. Please contact us if you require a custom solution.

FS-RWD-28.6-14.3-3.175-PPOL-700-900-72

Fused Silica window, 28.6mm x 14.3mm (+0/-0.25mm), 3.175mm (+/-0.25mm) thick, λ/10 transmitted wavefront distortion, 10-5 scratch-dig

Coating side 1: >85%R (av.) s-POL & >85%T (av.) p-POL @

700-900nm / 72°

Coating side 2: AR (<2%R avg.) @ 700-900m / 72° p-POL

FS-ECPOL-25.4-700-900

Fused Silica cube polariser, optically contacted, 1” x 1” x 1.38” (25.4mm x 25.4mm x 35.0mm), λ/8 transmitted wavefront distortion, 10-5 scratch-dig, polarising coating immersed

Coating immersed: >99.5%R sPOL & >95%T p-POL @ 700-900nm / 54° low GDD coating

Coating side 2: AR (<0.5%R) @ 700-900nm / 0°

FS-RWD-60.0-20.0-3.175-PPOL-

Fused Silica window, 60.0mm x 20.0mm (+0/-0.25mm), 3.175mm (+/-0.25mm) thick, λ/4 transmitted wavefront distortion, 10-5 scratch-dig

Coating side 1: >85%R (av.) s-POL & >85%T (av.) p-POL @ 700-900nm / 72°

Coating side 2: AR (<2%R avg.) @ 700-900m / 72° p-POL

FS-ECPOL-50.8-700-900

Fused Silica cube polariser, optically contacted, 2” x 2” x 2.76” (50.8mm x 50.8mm x 70mm), λ/8 transmitted wavefront distortion, 10-5 scratch-dig, polarising coating immersed

Coating immersed: >99.5%R sPOL & >95%T p-POL @ 700-900nm / 54° low GDD coating

Coating side 2: AR (<0.5%R) @ 700-900nm / 0°