Group delay dispersion (GDD) is an important optical phenomenon observed in the study of wave propagation, especially in ultrafast laser optics. It refers to the variation in the timing of different parts of an ultrafast laser pulse as it reflects off of optical components, such as mirrors. Understanding GDD is crucial for analysing how these reflective surfaces stretch or compress the pulse.

Ultrafast pulsed lasers have a broader spectrum than single wavelength lasers, typically around 750-850nm. To achieve an ultrashort pulse, wavelengths within the 750-850nm need to be overlayed.

The material and coatings of optical components used in a laser system effect the shape of a laser pulse. Since the refractive index of an optical material changes with the wavelength – something known as dispersion – and given the broadband nature of ultrafast laser pulses, in such systems there is a strong propensity to pulse distortion.

Ideally no change of the refractive index is wanted. The group delay dispersion (GDD) provides a gauge of the effect that an optical coating or element has on the pulse shape. If the GDD is zero, no distortion of the pulse takes place. Please see our technical paper for a more scientific explanation of this.

In simple terms, scientists and laser system users would prefer no pulse distortion and a flat response GDD. This would allow for the best reflected or transmitted pulse. i.e. All wavelengths reflected or transmitted at the same GDD.

Laser Mirrors and Group Delay Dispersion

The greater the number of mirrors in a laser system the greater the GDD effect this can have. Furthermore polarisations can also have an effect, with P-pol always being narrower bandwidth and reflecting less than S-pol. In our experience, system users tend to prefer P-pol.

The effect of GDD in Coating designs

Optical coatings serve to both protect the component from laser damage as well as control reflectance and refraction. When it comes to mirrors, understanding how GDD affects reflectance is an important consideration in component selection.

Protected silver mirrors

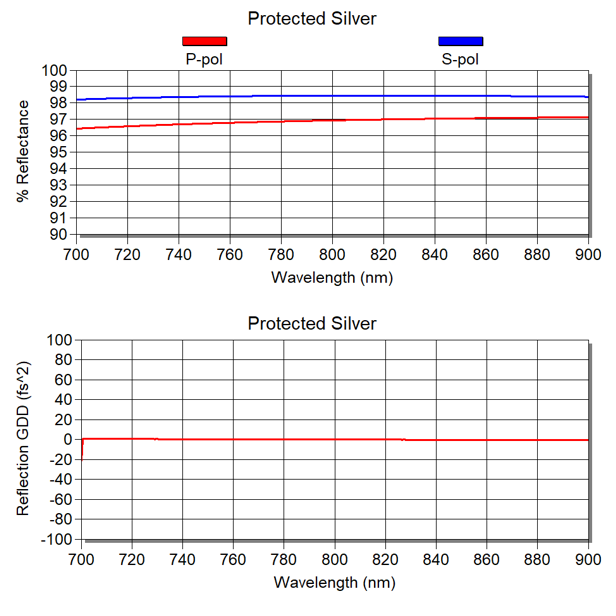

A simple and inexpensive protected silver mirror works very well for both effective reflectance and consistently low GDD.

However if a reflectance of 97% is insufficient then a silver mirror is not the right solution. Furthermore, such mirrors have low laser damage threshold (LDT) properties.

Designers of high-energy pulsed laser systems want to maximise the overall reflectance of beams and ensure the components have the highest practical LDT. Today’s lasers, especially those in large government labs, have so much power that these metal coatings would disintegrate after just a single shot.

We must therefore consider dielectric mirrors which can withstand much higher fluence than a highly absorbing metal layer.

Dielectric mirrors

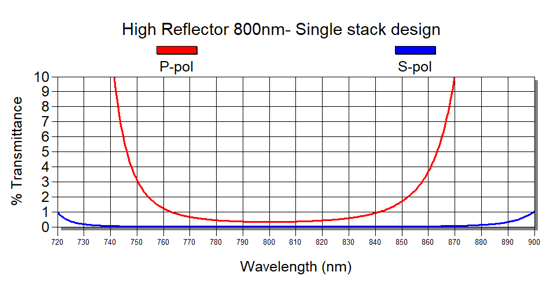

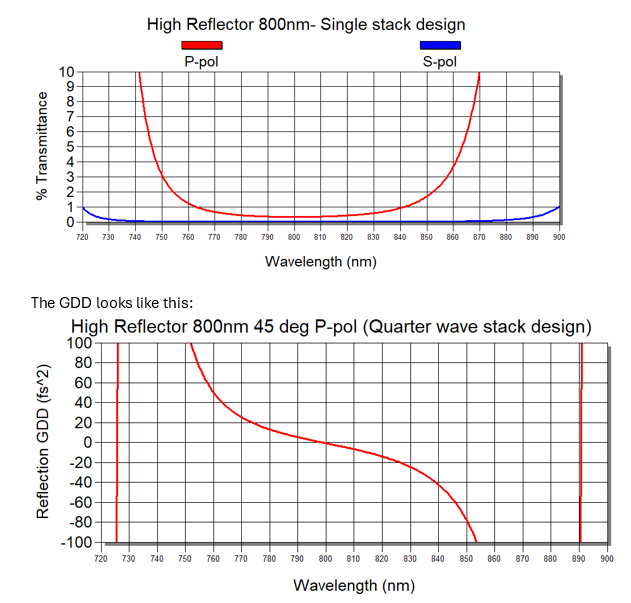

Dielectric coatings offer a much higher reflectance than protected silver coatings and a have a higher laser damage threshold. However, they have limited bandwidths. The bandwidth of a high reflector is governed by the difference between the refractive indices of the (typically two) coating materials. For instance, a typical high power quarter wave stack design gives a bandwidth or around 80nm at 45 degrees P-pol and 180nm in S-pol. The plot in the graph below illustrates the standard TTS mirror from Manx Precision Optics at 45 degrees angle of incidence.

Broader spectrum ultrafast lasers

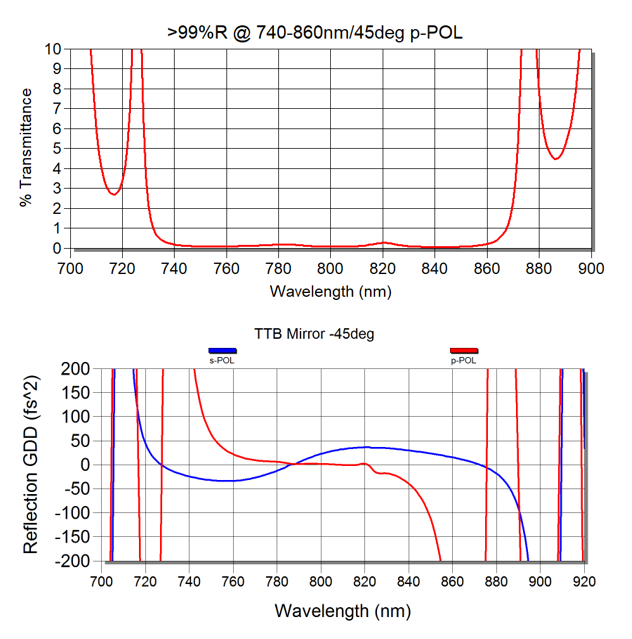

Some ultrafast lasers have a broader output spectrum e.g. 100nm in P-pol. This requires a coating design based on the same high power coating materials but with much more complicated design comprised of many more layers. In simple terms, the more layers a design has, the more complicated the design is to manufacture. This also means it is harder to maintain a flat response GDD.

When choosing mirrors for ultrafast high-energy lasers, it pays to work with a supplier experienced in making coating designs optimised to provide the best overall characteristics, i.e. broad bandwidth, flat GDD response and high laser damage threshold (LDT). Manx Precision Optics, or MPO, have been working with and perfecting complicated coating designs for nearly thirty years. The below plot is our standard TTB mirror.

Metal hybrid mirrors

There is growing demand for even broader reflectance and also reflection at other wavelengths (633, 405, 905nm etc.) for beam alignment.

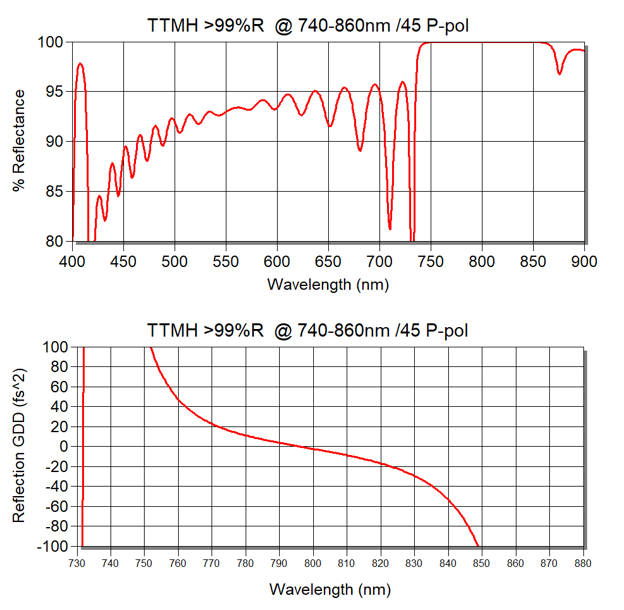

Metal hybrid mirrors are an effective solution for these needs. These mirrors have a thin layer of silver topped by a dielectric coating. The silver provides effective broadband reflectance over a wide wavelength range whilst the dielectric coating on top deals with the high energy and provides a near identical LDT to a dielectric quarter wave stack design (TTS Mirror). The graph below shows the plot for a TTMH mirror from MPO.

Wrap up

Understanding and precisely controlling GDD is critical for ensuring optimal performance in ultrafast laser systems, where both controlling pulse shape and timing are paramount. However, meeting the increasing demand for broader bandwidths, higher reflectivity, flatter GDD responses, and greater LDT poses significant design challenges. Balancing all four factors often requires trade-offs, and achieving perfect performance across the board can be an intricate, if not impossible, task.

When it comes to selecting mirrors for your laser system, it pays to talk to the experts. Using our considerable experience MPO can design a custom solution for your individual needs. Get in touch for a no-obligation discussion. We will always aim to offer the most straightforward solution and avoid overspecification.