HIGH-ENERGY LASER POLARISATION OPTICS

Polarisation optics are components used to manipulate the polarisation state of light. However, for high-energy applications, ensuring precise, accurate and lasting performance is far from simple. Components must function within exacting tolerances while withstanding high levels of laser fluence. Sub-optimal material selection or coating design risks laser induced damage (LID) or thermal lensing, which can compromise beam quality and shorten the component’s operational lifespan.

At Manx Precision Optics, we understand that reliability under high power is paramount. Our expertise integrates optical design with a complete in-house manufacturing capability. We control the entire process – from substrate shaping, precision polishing and optical contacting to the application of high-LIDT coatings. This allows us to engineer robust polarisers, waveplates and beamsplitters that maintain their specified performance in high-energy laser systems.

Our Polarisation Optics

HIGH-ENERGY

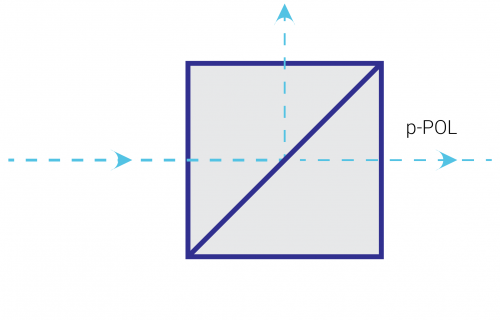

CUBE POLARISERS

For separating s- and p-polarisation states with high extinction ratios. Precision polished and optically contacted for high-power handling.

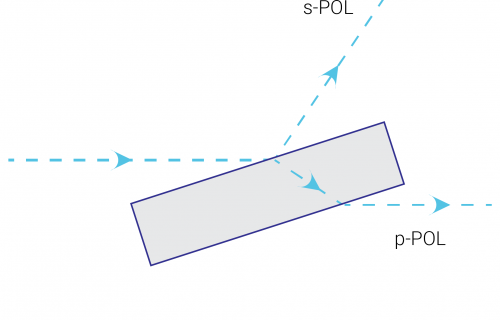

ULTRAFAST

POLARISERS

Specialised thin-film polarisers designed with minimal group delay dispersion (GDD), optimised for femtosecond and picosecond pulse durations.

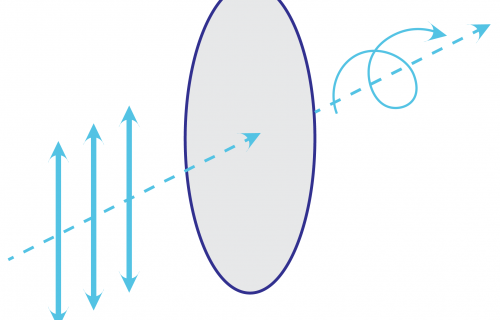

HIGH-ENERGY WAVEPLATES

Zero-order and multi-order quartz waveplates for accurately rotating polarisation. Available with air-spaced or optically contacted designs to minimise damage risk.

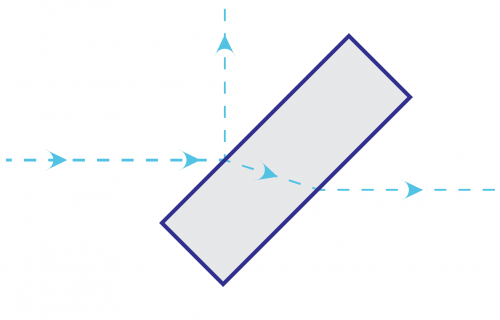

HIGH-ENERGY BEAMSPLITERS

Robust plate and cube beamsplitters for dividing high-power beams with precise splitting ratios and high surface flatness.

Manufacturing and Technical Capabilities

We manufacture our polarisation optics in-house, ensuring complete control over surface quality and coating performance. Our capabilities include:

- High laser induced damage thresholds (LIDT): Verified for pulsed and CW operations to ensure longevity in high-power systems.

- Precision polishing: Achieving better than 10-5 scratch-dig surface quality to minimise scatter and absorption.

- Custom wavelength ranges: From UV (e.g. 266nm) to IR (e.g. 1064nm and beyond) to suit specific laser lines.

Discuss Your Requirements

We offer a wide range of standard polarisation optics but our aim is to meet our customers’ needs, no matter how challenging. If that means designing and fabricating a custom solution for your specific requirements, then that’s what we do. Contact our technical team to discuss your application.

Frequently Asked Questions

What is the difference between a polariser and a waveplate?

A polariser is used to transmit light of one polarisation while blocking others (i.e. to create polarised light). A waveplate is used to change or rotate the polarisation state of light that is already polarised.

What does the “extinction ratio” of a polariser mean?

The extinction ratio is a measure of how well a polariser blocks the unwanted polarisation state. A higher ratio indicates better performance and a more purely polarised output beam.

What is a zero-order waveplate and why is it useful?

A zero-order waveplate is constructed from two multi-order plates aligned to have a net retardation of the desired value (e.g. half-wave or quarter-wave). This design makes its performance less sensitive to changes in wavelength and temperature compared to a standard multi-order waveplate.