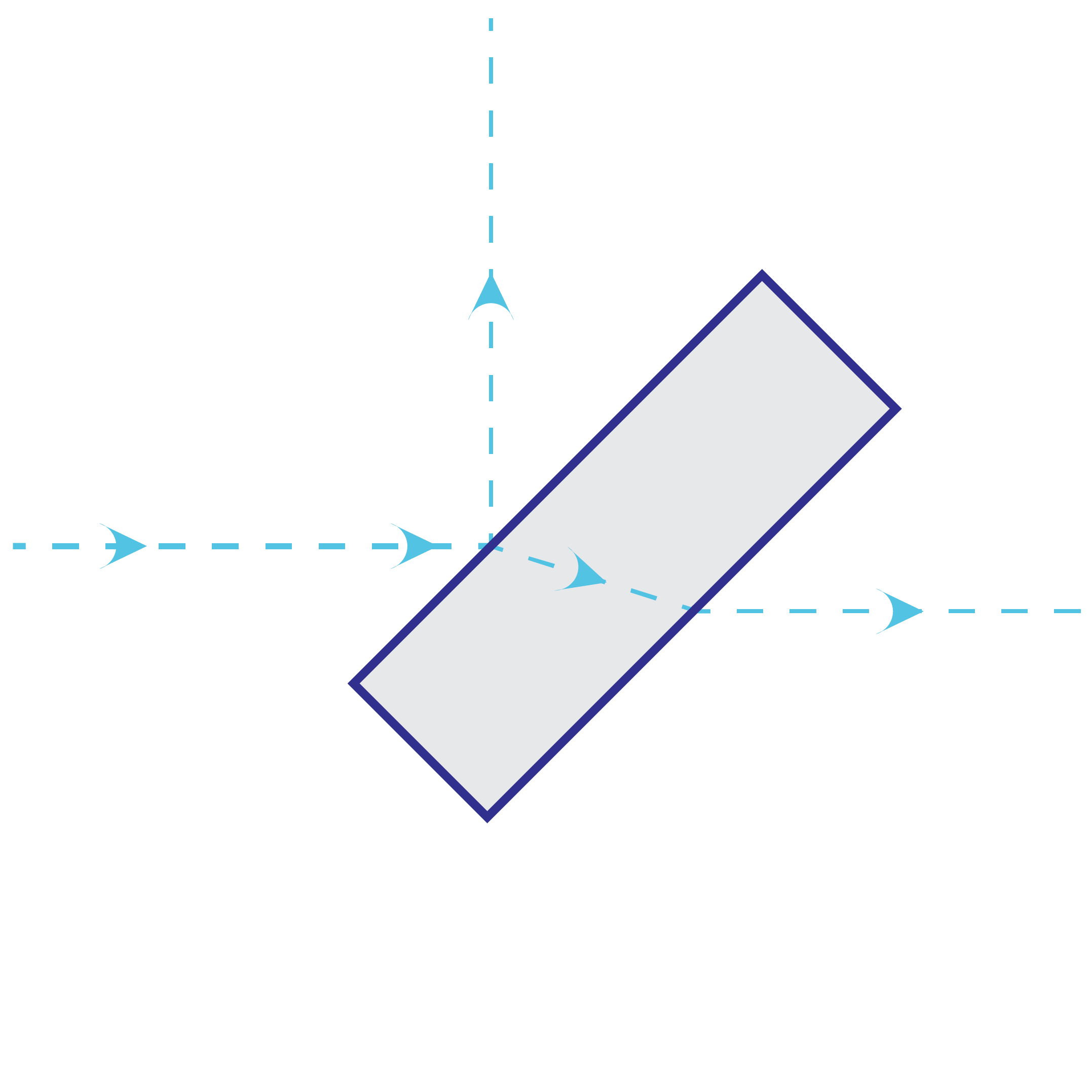

HIGH-ENERGY LASER BEAMSPLITTERS

MPO’s high-energy laser plate beamsplitters offer exceptionally accurate and precise beam separation.

Optimal reflectivity and transmissivity results from the superior surface quality of our beamsplitters, the specific front surface coatings applied to components and the high degree of flatness after coating. The coating is also designed to reflect and transmit a specific amount of the incident beam, depending on the desired split ratio. Additionally the high laser-induced damage threshold (LIDT) nature of the coating ensure resistance to the high-power densities of high-energy lasers and so the durability of the plate beamsplitter.

Our plate beamsplitters can be custom made to any combination of separation ratios, polarisations, and wavelength ranges, making them ideal for a wide range of applications. Whether you need a beamsplitter for a high-energy laser system, a medical laser system, or a scientific laser system, we have the solution for you. Contact us for more information.

SPECIFICATIONS

Please select the required beamsplitter coating from the table of standard splitting ratios/AR coatings below, applicable to substrates up to 101mm in diameter.

If you need beamsplitters larger than 101mm in diameter or if you cannot find the coating you require in the table, please do not hesitate to contact us for a quotation. We might even have a suitable optic readily available from stock.

COATING TYPE |

WAVELENGTH – 355 nm/ 532 nm / 633 nm / 800 nm / 1030 nm or 1064 nm |

| Partial reflector – splitting ratio 20% / 50% / 80% / |

Standard coating for 1” – 4” diameter substrate |

| 90% / 95% or 98% at 0º or 45º rand.-POL | |

| Anti reflection (AR) coating for 0º or 45º rand.-POL |

Standard coating for 1” – 4” diameter substrate |

Partial reflectors reflectivity tolerance:

+/- 3% for 20%R and 50%R

+/- 2% for 80%R and 90%R

+/- 1% for 95%R

+/-0.75%R for 98%R

Anti-reflection coatings: <0.25%R for 0º and <1%R for 45º rand.-POL