high-ENERGY LASER waveplates

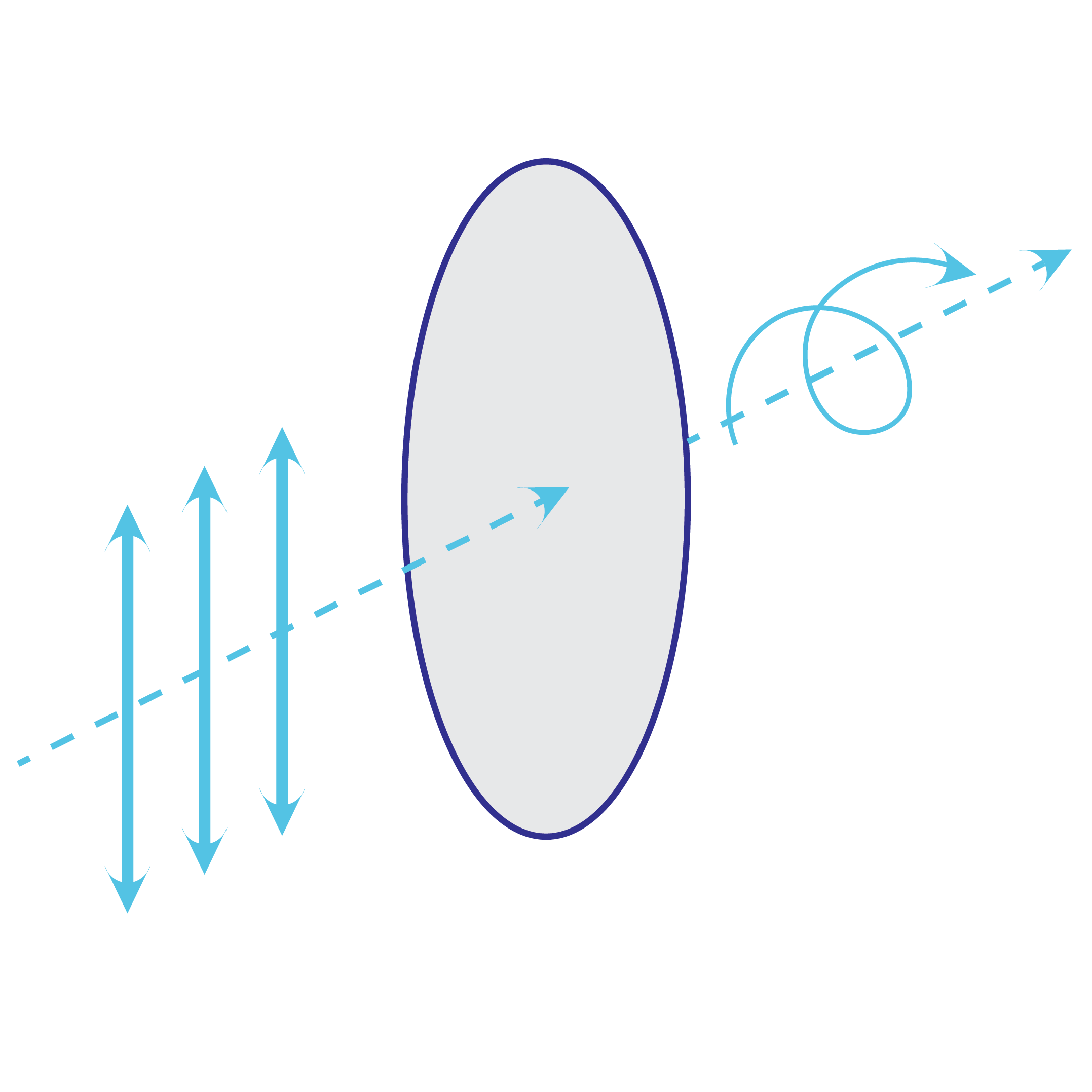

MPO high-energy laser waveplates are designed for manipulation, polarisation and control applications. Our ultra-flat, crystal quartz waveplates are fabricated with low loss anti-reflection high laser-induced damage threshold (LIDT) coatings to ensure exceptional durability and optical performance. They provide unmatched wavefront distortion, parallelism, and surface quality, minimising beam distortion and maximising laser efficiency.

Our standard product range includes mounted and unmounted waveplates with diameters greater than 2 inches, zero, quarter and half-wave and multiple order waveplates. They are suitable for the most demanding applications in UV, through visible to infrared wavelengths.

We welcome enquiries for custom products other than standard operational wavelengths, different waveplate diameters and uncoated waveplates – please contact us.

MPO offers a wide range of waveplates to meet the needs of our customers. These include:

- Standard λ/2 and λ/4 waveplates: These waveplates are used to generate phase delays of λ/2 (half-wave) or λ/4 (quarter-wave) and are widely employed in polarisation control applications.

- Multiple order waveplates: These waveplates are designed for single wavelength lasers and provide high performance over a narrow wavelength range.

- Zero order waveplates: These waveplates are designed for broader wavelength applications and provide good performance over a wide wavelength range.

- Air-spaced waveplates: These waveplates are designed for high power broadband applications and can withstand high laser power densities.

MPO also offers custom waveplates tailored to specific application requirements. Whether you need unique phase retardation values, unusual dimensions, or specialised coatings, MPO can deliver.

All MPO waveplates can be mounted or unmounted and can be supplied uncoated if required.

Key characteristics of our waveplates

- High LIDT for intense laser applications

- Exceptionally low wavefront distortion and parallelism for minimal beam distortion

- Superior, ultra flat surface quality for optimal light transmission

- Crystal quartz based

- Low-loss anti-reflection (AR) coatings

- High laser-induced damage threshold (LIDT)

- Minimal wavefront distortion

Specifications

- Synthetic single crystal quartz, dimensional tolerance: +0/-0.25mm diameter, λ/10 transmitted wavefront distortion, 10-5 scratch-dig, better than 0.5 arc sec parallel, >85% clear aperture retardation tolerance: λ/100 – λ/600 typical (dependent on wavelength) unmounted

- Both faces AR (<0.25%R) coated at operational wavelength.

The Manx Precision Optics part number for waveplates follows the following pattern:

- Z (for zero order) 2 (for half wave retardation) Operational

- CQWP- or – diameter in mm – or – wavelength

- M (for multiple order) 4 (for quarter wave retardation) in nm

STANDARD DIAMETERS

- 25.4mm (1”) 50.8mm (2”)

STANDARD OPERATIONAL WAVELENGTHS IN NM

248 |

257 |

266 |

308 |

355 |

400 |

405 |

488 |

514 |

532 |

633 |

670 |

694 |

780 |

800 |

810 |

1030 |

1047 |

1053 |

1064 |

1315 |

1319 |

1550 |

For example: CQWP-Z-25.4-2-248 is a 25.4mm diameter, zero order, half wave retardation waveplate for 248nm.

All waveplates can also be mounted. When mounted, the 25.4mm diameter waveplates will have a minimum 22.1mm clear aperture and an outside mount diameter of 38.1mm, while the mounted 50.8mm diameter waveplates will have a minimum 44.2mm clear aperture and an outside mount diameter of 76.2mm.