Precision Roof Mirrors for Ultrafast and High-Energy Systems

High-energy ultrafast laser systems present a dual challenge for optical components. They must manage temporal dispersion to preserve the integrity of femtosecond and picosecond pulses, while simultaneously handling extreme peak powers without thermal distortion or damage.

While solid glass prisms can in theory perform the same geometric function, their bulk material is often unsuitable for these applications, as it introduces both significant group delay dispersion (GDD) and a risk of thermal absorption.

The MPO roof mirror is the engineered alternative. Its air-path design fundamentally decouples the optical function from a bulk material. This simultaneously eliminates the bulk GDD that broadens ultrafast pulses and removes the risk of material absorption that leads to thermal damage, making it the obvious choice where both pulse integrity and power handling are critically important.

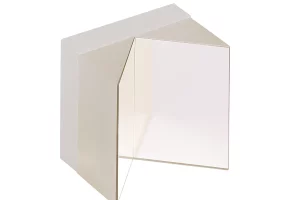

What is a Roof Mirror?

A roof mirror functions as a one-dimensional retroreflector, reflecting a light beam back along a path parallel to its original direction. This is achieved by the double reflection from the two surfaces set at a precise 90° dihedral angle.

Key optical principles include:

- Retroreflection: The 90° angle between the mirrors ensures an incoming ray is reflected back at 180°, anti-parallel to its source. This effect is stable and independent of the initial angle of incidence.

- Beam Orientation: A single mirror flips a beam’s profile (a parity reversal). The roof mirror’s double reflection avoids this, instead rotating the beam profile by 180° around the roofline axis. This predictable rotation preserves the beam’s coordinate system, which is significant for maintaining the orientation of non-symmetrical beams in a folded optical path.

- Equivalent mirror: For design purposes, the double reflection can be simplified to a single reflection from an “equivalent mirror” located at the roofline. This allows a roof mirror to replace a standard flat mirror in a system to gain its benefits without needing to redesign the optical path length.

The Air-Path Advantage: Why Choose an MPO Roof Mirror?

The performance of a solid prism is limited by the properties of its glass, whereas a roof mirror’s performance is defined by its surfaces and coatings. This provides significant advantages:

- Zero bulk dispersion: Total Group Delay Dispersion (GDD) has two sources: dispersion from the bulk material the pulse travels through, and dispersion from the reflective coating. The roof mirror’s air-path design means it has no bulk material and therefore introduces zero bulk GDD. This preserves the temporal integrity of femtosecond and picosecond pulses and allows us to control the total GDD of the component exclusively through the application of advanced dielectric coatings.

- No chromatic aberration or absorption: The air-path is ideal for high-energy systems or broadband applications as it eliminates the thermal lensing, material absorption, and chromatic aberration that are inherent in solid glass optics.

- Inherent alignment stability: The assembly is exceptionally insensitive to rotation around its roofline axis. This passive stability is ideal for building robust systems, laser resonators, and optical delay lines.

- Integrated polarisation control: The double reflection can be used to predictably rotate the angle of linear polarisation. By orienting the mirror correctly, it can act as a 90° rotator, which reduces component count and simplifies system design.

MPO Roof Mirror Specifications

We engineer our roof mirrors to meet the highest performance standards for demanding applications.

- Substrate materials: We use thermally stable materials such as UV Grade Fused Silica and Zerodur®.

- Coating options: Our capabilities include high-LIDT dielectric coatings, specialised low-GDD and chirped coatings for ultrafast use, and broadband metallic coatings.

- Angular accuracy: We manufacture assemblies with an exceptionally precise dihedral angle, with tolerances to within ±10 arcseconds.

- Surface quality and flatness: We produce high-quality surfaces with a flatness of λ/10 or better to preserve the wavefront quality of your beam.

Discuss Your Requirements

A roof mirror is a high-specification component that must be precisely matched to your system’s requirements. Our aim is to meet this challenge by working directly with you to design and fabricate a custom solution that ensures ultimate performance and reliability. Contact our technical team to discuss your application.

Frequently Asked Questions

What is the main advantage of a roof mirror over a solid roof prism?

The primary advantage is the air-path design, which means the roof mirror is free from the bulk material effects that limit solid prisms, such as group delay dispersion, thermal absorption, and chromatic aberration.

How is a roof mirror different from a corner-cube retroreflector?

A roof mirror provides retroreflection in one dimension (a single plane) and preserves the image parity. A corner-cube provides retroreflection in three dimensions but reverses the image parity.

What is a dihedral angle?

It is the angle between the two reflective surfaces. In a roof mirror, this is manufactured to be 90° with extreme precision, which is what enables it to function as a retror