Precision Laser Mirrors for High-Performance Systems

Ultrafast laser mirrors are specialised optical components designed to manage the unique demands of high-energy femtosecond and picosecond laser systems. Unlike standard mirrors, their performance is defined by a complex balance – providing precise dispersion control while maintaining a high laser-induced damage threshold (LIDT) to withstand extreme peak powers.

At Manx Precision Optics, our expertise is in translating a deep understanding of optical theory – from coating design to material science – into the engineering of high-specification mirrors that are precisely optimised for your specific high-energy and ultrafast laser requirements. The result is a component that delivers its function without compromise, preserving pulse integrity in applications from multiphoton microscopy to advanced materials processing.

Our Laser Line Mirror Configurations

We manufacture laser line mirrors for use at any specific wavelength. Our two primary configurations are optimised for the most common angles of incidence:

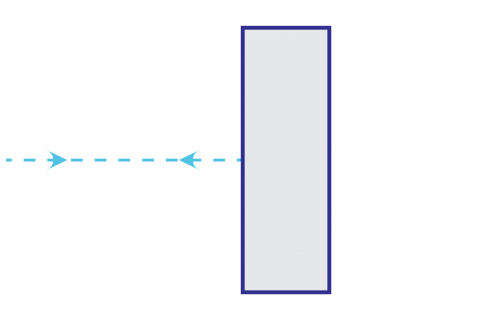

- 0° Incidence Laser Line Mirrors: Designed for beams at a normal or near-normal angle to the mirror surface. Standard product specification and performance data

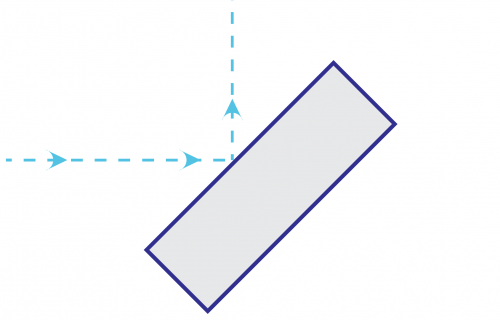

- 45° Incidence Laser Line Mirrors: Engineered for applications that require the beam to be redirected at a 90° angle, such as in beam steering and routing. Standard product specification and performance data

Explore Our Standard and Specialised Mirror Ranges

In addition to custom laser line mirrors, we also offer a portfolio of semi-standard, high-performance components for specific applications.

- Ultrafast laser mirrors: For applications requiring precise dispersion control in femtosecond and picosecond systems. This range includes our TTS, TTB (broadband), and TTW (very broad) mirrors.

- Metal-coated mirrors: For applications requiring consistent, high reflectivity across a broad spectral range. This range includes our TTMP (metal) and TTMH (metal hybrid) mirrors.

- Roof mirrors: For applications that require inverting an image or redirecting a beam path by 90°.

Key Features of MPO Laser Line Mirrors

- Unparalleled laser-induced damage threshold (LIDT): Engineered to withstand the intense power of high-energy lasers without degradation or damage.

- Exceptional reflectivity: Reflecting over 99.8% of incident light at the required wavelength to maximise laser power.

- Flatness after coating: Characterised by the highest degree of flatness after coating for ultimate wavefront performance.

- Exceptional surface quality: Fabricated on high-purity substrates to maintain beam quality and prevent distortion for accurate, focused laser beams.

- Durable construction: Built to withstand harsh environmental conditions for long-lasting performance.

The MPO Advantage

Our mirrors are the culmination of decades of expertise and an unwavering commitment to quality. We utilise advanced manufacturing techniques and rigorous quality control measures to ensure that each mirror meets the highest standards of performance and reliability.

Discuss Your Requirements

We offer a wide range of standard products, but our aim is to meet our customers’ needs, no matter how challenging. If that means designing and fabricating a custom solution for your specific requirements, then that’s what we do. Contact our technical team to discuss your application.

COMPONENTS FOR ULTRAFAST LASERS

Visit the section on TT mirrors to find out more about our range of optical mirrors for ultrafast laser systems with very high reflectivity, low group delay dispersion (GDD) and high laser-induced damage threshold (LIDT).

Frequently Asked Questions

Q: What is the difference between 0° and 45° incidence laser line mirrors?

A: The angle of incidence refers to the angle at which the laser beam strikes the mirror surface. Our 0° incidence mirrors are designed for beams arriving at a normal or near-normal angle, reflecting the light directly back along its path. In contrast, 45° incidence mirrors are engineered to redirect the beam at a 90° angle, making them essential for applications such as beam steering and routing within an optical setup.

Q: What reflectivity performance can I expect from these mirrors?

Our laser line mirrors are engineered to deliver exceptional efficiency, reflecting over 99.8% of incident light at the design wavelength. This high reflectivity is significant for maximising laser power throughput and maintaining system efficiency, particularly in high-energy applications.

Q: Can you manufacture mirrors for specific wavelengths?

A: Yes, while we offer standard configurations, we manufacture laser line mirrors for use at any specific wavelength. Whether you require components for standard laser lines or a custom wavelength for a unique application, we can design and fabricate the coating and substrate to meet your exact requirements.

Q: How do your mirrors handle high-energy laser pulses?

A: We prioritise the Laser-Induced Damage Threshold (LIDT) in our designs. By combining high-purity substrates with advanced coating techniques, our mirrors are built to withstand the intense peak powers of high-energy lasers without degradation. This ensures long-term reliability and pulse integrity in demanding environments.

Q: Why is “flatness after coating” a significant specification?

A: The coating process can sometimes introduce stress that warps the optical surface, leading to wavefront distortion. At MPO, we focus on maintaining the highest degree of flatness after the coating is applied. This ensures that the reflected wavefront remains pristine, which is vital for applications requiring high precision and beam quality.